Flanges

Focused Products

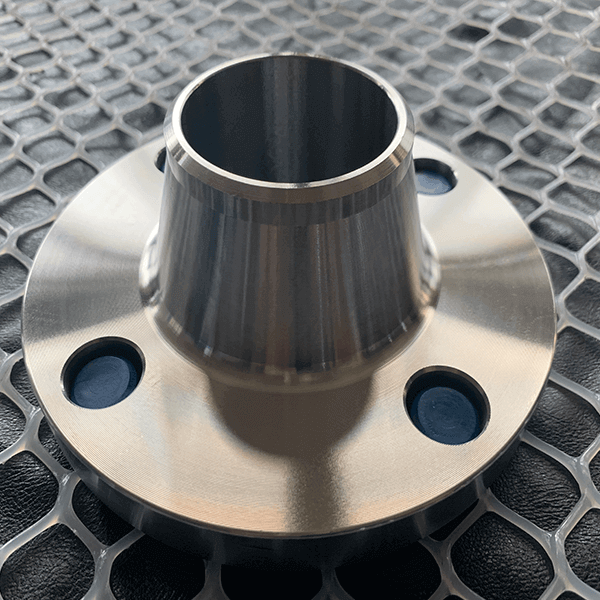

LONG WELDNECK FLANGE

Nascent fittings INC is a well-known Manufacture & Exporter of Long weld neck flanges in India and throughout the world. We provide cost-effective, dependable, and high-quality superior flanges to our customers. Long weld neck flange (LWN flange), is used for high pressure situations, integral hub weld neck flanges are used and for very high pressure cases Long Welding Neck flanges are preferred. In this case, the weld are far from the ring to avoid bending stresses and weld stress being combined The Long Weld neck Flange was designed to be used in place of a Weld Neck Flange and piece of pipe for a bolt up connection to the vessel. This design reduced the stress on the neck and transferred it to the base where it connected to the vessel. The Long Weld Neck Flange is the most common of the self-reinforced nozzle designs. The two types are the heavy barrel with a long weld neck and the equal long weld neck barrel with a variety of shapes.

Enquiry NowThis kind of flange helps to balance pressure and temperature changes in the liquid that is flowing in the pipeline. Long weld neck flanges are often found as anchors in water mains. Because they can withstand higher pressures, this flange can be used to connect larger networks of pipes, such as those in a factory. Long weld neck flanges can also be used in expansion bends or extending or reducing pipe sizes. It is necessary in vessels that require an extended neck or hub to function as an extension. It is used in the chemical, petroleum, oil & gas industry that experience high levels of stress and fluctuating temperatures.

CARBON STEEL SPECIFICATION:

- Size : 1/2″ NB to 80″ NB

- Dimensions: ANSI/ASME B 16.5, B16.47, B16.36, DIN Standard, JIS Standard, EN1902-1 Standard, UNI Standard, BS10 Standard, BS4504 Standard, API Standard etc.

- Class : 150# , 300#, 400#, 600#, 900#, 1500#, 2500#

- Schedule : 10/20/40/80/100/120/160/XXS

- Carbon Steel : ASTM A 105

- Carbon Steel : DIN Standard – EN 10222-2/ EN 10222-4 – P235GH / P245GH / P265GH / P280GH / P295GH / P355N / P355NH / P285NH / P285QH

- Other Services: Hot Dip Galvanizing, Sand Blasting, Special Threading.

ALLOY STEEL & LTCS SPECIFICATION:

- Size : 1/2″ NB to 80″ NB

- Dimensions: ANSI/ASME B 16.5, B16.47, B16.36, DIN Standard, JIS Standard, EN1902-1 Standard, UNI Standard, BS10 Standard, BS4504 Standard, API Standard etc.

- Class : 150# , 300#, 400#, 600#, 900#, 1500#, 2500#

- Schedule : 10/20/40/80/100/120/160/XXS

- Alloy Steel : ASTM A 182-F5, F9, F11, F21, F22 & F91

- Low Temp.CS : A 350 LF2

- Other Services : Hot Dip Galvanizing, Sand Blasting, Special Threading.

STAINLESS STEEL & DUPLEX STEEL SPECIFICATION:

- Size : 1/2″ NB to 64″ NB

- Dimensions: ANSI/ASME B 16.5, B16.47, B16.36, DIN Standard, JIS Standard, EN1902-1 Standard, UNI Standard, BS10 Standard, BS4504 Standard, API Standard etc.

- Class : 150# , 300#, 400#, 600#, 900#, 1500#, 2500#

- Schedule : 10/20/40/80/100/120/160/XXS

- Stainless Steel : ASTM A 182 F -304/304H/304L/316/316H/316L/316Ti/309/310/317L/321/347/904L,XM19

- Stainless Steel : DIN Standard EN 10222-5 1.4301/1.4307/1.4401/1.4404/1.4529/1.4571/1.4541/1.4410/1.4550/1.4335/1.4539

- Duplex Steel : ASTM A 182 F -51, F 53, F 55

NICKEL ALLOYS SPECIFICATION:

- Size : 1/2″ NB to 48″ NB

- Dimensions: ANSI/ASME B 16.5, B16.47, B16.36, DIN Standard, JIS Standard, EN1902-1 Standard, UNI Standard, BS10 Standard, BS4504 Standard, API Standard etc.

- Class : 150# , 300#, 400#, 600#, 900#, 1500#, 2500#

- Schedule : 10/20/40/80/100/120/160/XXS

- Copper Nickel : C70600(90:10), C71500(70:30), C71640

- Nickel : UNS N02200, N02201

- Monel : UNS N04400, N05500, Alloy 20

- Inconel : UNS N06600, N06601, N06625, N08800, N08810, N08825,

- Hastelloy : UNS N10276, N06022, N10665, N06455,

- SMO 254 Grade UNS S31254

- Aluminium : ASTM B247, B361 – 2024, 6061, 6063, 6101, 7075.

- Titanium : ASTM B381 – Grade 1, Grade 2, Grade 4, Grade 5, Grade 6, Grade 7, Grade 9, Grade 19, Grade 23

Test Certificate:

- Manufacturer test Certificate En 10204, 3.1 & 3.2

- IBR Test Certificate Form IIIC

- TPI Inspection Release Note (as per customer requirement)

180 Degree Return Cap

Posted

Job Description

Nascent fittings INC is a well-known Manufacture & Exporter of Long weld neck flanges in India and throughout the world. We provide cost-effective, dependable, and high-quality superior flanges to our customers. Long weld neck flange (LWN flange), is used for high pressure situations, integral hub weld neck flanges are used and for very high pressure cases Long Welding Neck flanges are preferred. In this case, the weld are far from the ring to avoid bending stresses and weld stress being combined The Long Weld neck Flange was designed to be used in place of a Weld Neck Flange and piece of pipe for a bolt up connection to the vessel. This design reduced the stress on the neck and transferred it to the base where it connected to the vessel. The Long Weld Neck Flange is the most common of the self-reinforced nozzle designs. The two types are the heavy barrel with a long weld neck and the equal long weld neck barrel with a variety of shapes.